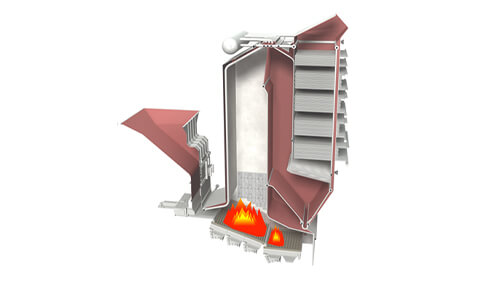

Examples of DX initiatives Waste-to-Energy plants:

Improving Efficiency Using Combustion Predictions

Background

- ・Currently, it is difficult to secure operators for Waste-to-Energy plants, and it is even more challenging to find skilled operators with waste incineration expertise.

- ・There is a demand for labor-saving and manpower reduction measures to streamline plant operations and reduce the workload of operators.

Issues before the initiative

- ・The waste fed into incinerators is diverse and not uniform in quality, leading to fluctuations in combustion.

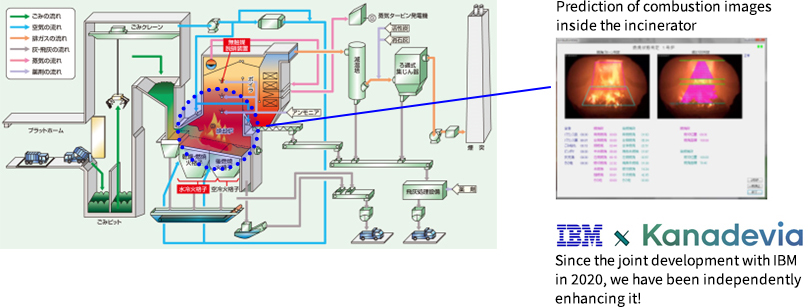

- ・In conventional automatic combustion systems, skilled operators constantly monitor images inside the incinerator and process data and adjust operating parameters as needed to ensure the stable operation of the incinerator.

Response

- ・Advanced in Automatic Combustion Control.

- ・Utilized AI to predict the combustion state several minutes ahead, and to adjust operating parameters and provide operational support in place of operators.

Necessary data

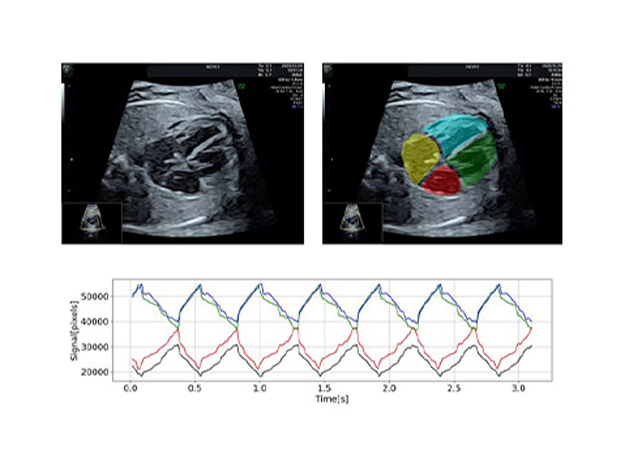

- ・Image data of the combustion state inside the incinerator

- ・Combustion process data

Outcome

- ・Stabilization of Waste-to-Energy generation through improved combustion stability

- ・Reduction of operators' workload

Future issues

Further improvements in accuracy, deployment to older Waste-to-Energy plants, and the establishment of AI-operated systems and maintenance systems are being pursued to achieve more stable combustion.