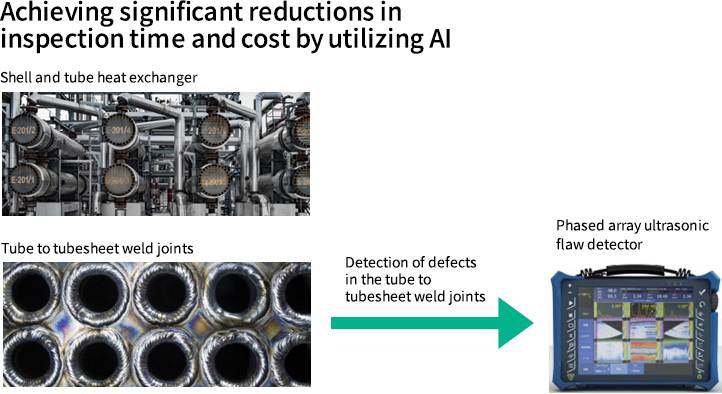

Examples of DX initiatives Phased Array UT Inspection System for Tube to Tubesheet Weld Joints:

kantanPAUT®

- ・Winner of the Grand Prize at the 2nd Deep Learning Business Awards

- ・Our case studies featured in the "Deep Learning Textbook: Official Text for the Deep Learning Generalist Certification (JDLA Deep Learning for GENERAL) 3rd Edition“

Background

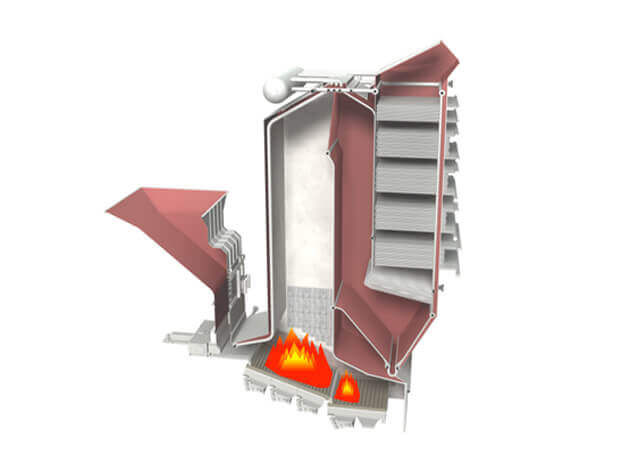

- ・Due to fluid leakage at the tube to tubesheet weld joints of the shell and tube heat exchanger during operation, a precise inspection becomes necessary.

Issues before the initiative

- ・The precise inspection of thousands of tube to tubesheet weld joints required an enormous amount of time and cost.

Response

- ・Developed an automated defect inspection system based on images of flaw detection data using AI.

Necessary data

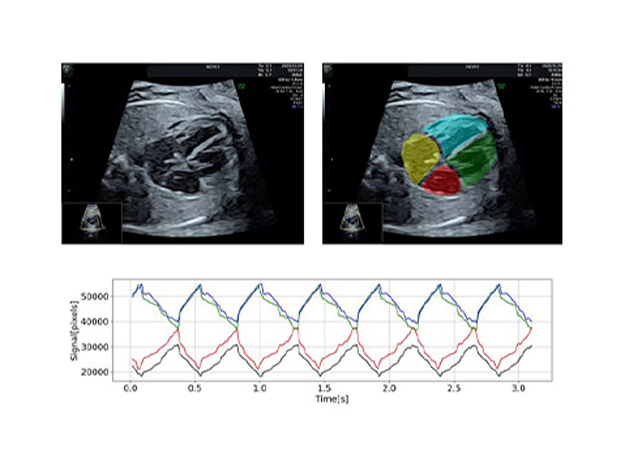

- ・Utilized phased array technology to image ultrasonic waveform data.

- ・Automatically acquired flaw detection data at 1° increments over the full 360°.

- ・Leveraged PaaS to automatically determine flaw detection data in the cloud.

Outcome

-

・Realized substantial savings in both inspection time and cost;

- 1.Visually re-evaluated only images that AI identifies as defective.

- 2.Accurately differentiated noise similar to defects to reduce false positives.

- 3.Reduced inspection time by approximately 80% compared to the traditional method.