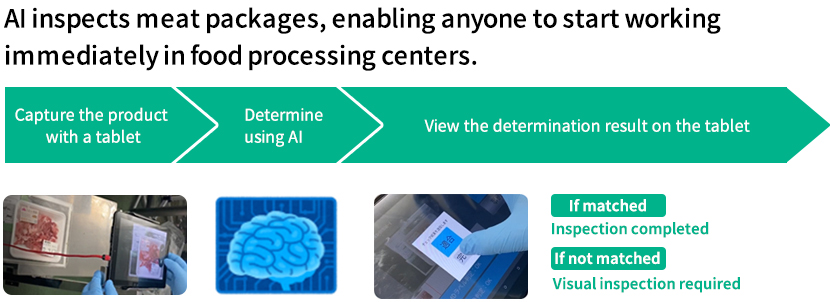

Examples of DX initiatives Remote Label Check Service

Background

- ・In food processing centers for meat, there is a process of arranging and packaging meat, followed by attaching product labels and price labels. It is necessary to attach the correct labels according to the type of meat (such as beef and pork) and its use (such as sliced or cut-off pieces). However, due to the production of a wide variety of small quantities, frequent human errors and a significant workload for workers have led to incidents where meat packages were shipped with incorrect labels.

Issues before the initiative

- ・Every time there is a change in product variety, workers pay close attention to visually confirm that the meat matches the labels, making it a challenge to prevent human errors and reduce workload. Additionally, only skilled workers are able to distinguish between the types of meat, and it takes several years of training to acquire this ability.

Response

- ・Developed an AI-based image recognition system.

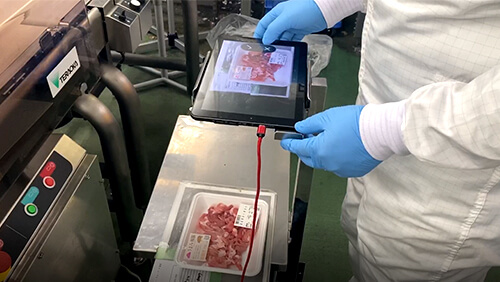

- ・Developed and launched "Remote Label Check Service," allowing food processing centers to make AI assessments remotely using tablets, administrative PCs, and a server installed at AI.TEC.

Necessary data

- ・Image data of meat packages

Outcome

- ・Even newcomers and foreign workers can start working immediately in food processing centers.

- ・If necessary, the meat package can be tracked using image records.