Occupational Health and Safety

Basic Approach and Policy

We promote safety activities throughout the Group based on our basic philosophy, Kanadevia Value, which states that safety is our top priority in all of our business activities. We believe that the origin of our safety-first policy stems from asking ourselves why safety is important and continuing to explore what we should do to ensure safety. Safety and security are the basis of human capital management and health management. We will continue to pursue safety in all processes from product design, manufacturing, construction, and operation, and create a safe and comfortable working environment for all people involved in our Group's business activities.

Targets

Structure and System

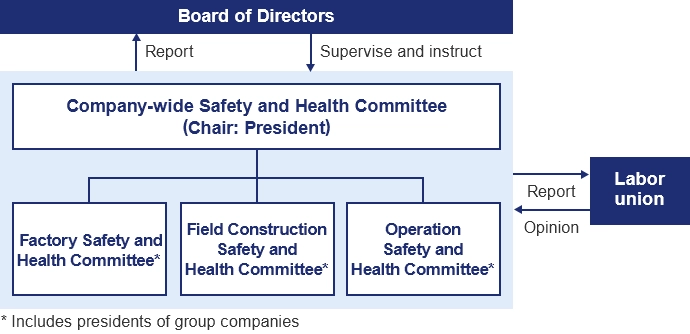

Company-wide Safety and Health Committee

In July 2023, we established a company-wide Safety and Health Committee, chaired by the President and including the general managers of each business headquarters and headquarters management department, to further improve the level of safety management in the Group. The committee formulates basic policies for safety and health management and raises issues, and the deliberations are reported to the Board of Directors.

Initiatives

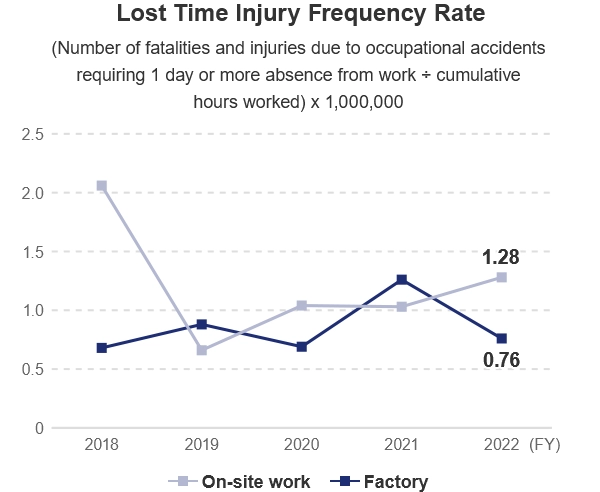

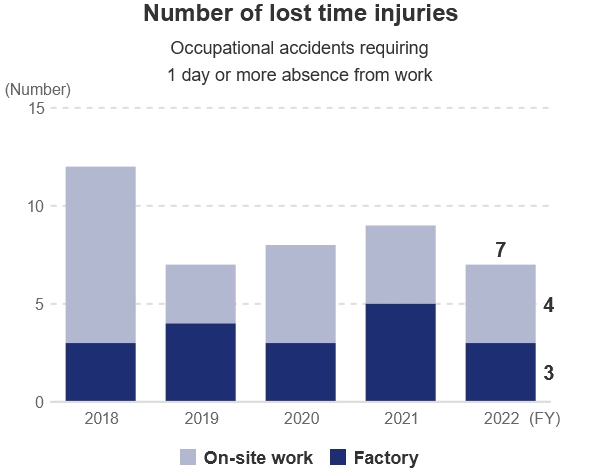

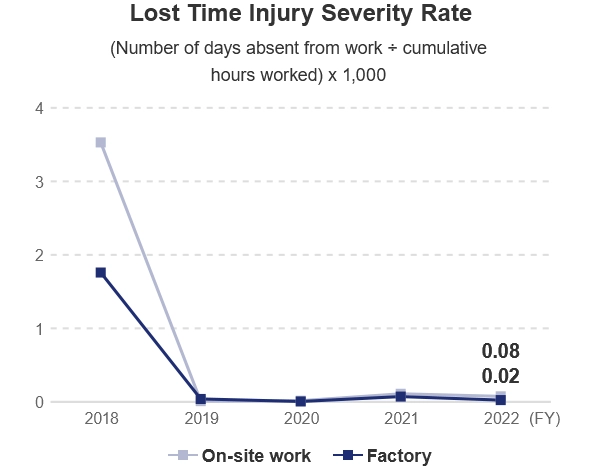

Track Records

- *On-site work: Total of domestic construction work (for projects where Kanadevia was the prime contractor, including subcontractors).

- *Factory: Domestic factories and group companies that conduct business activities on these premises in accordance with the principles of consolidated financial statements.

Safety Training

In June 2023, we held an eight-day (total of 40 hours) machinery and equipment safety training course led by the Japan Industrial Safety & Health Association for employees of the design and safety management departments at the headquarters in order to promote the safety-first philosophy and enhance our functions. This training is designed to ensure thorough risk assessment in all processes of machinery and equipment, from manufacturing to disposal, and will be incorporated into the Group’s training system to carry on the safety-first philosophy. We also use VR equipments and other specialized devices to simulate the hazards that can occur in the field, and we provide training to increase sensitivity to danger.

・Training on safety standards : 784 people

Enhancing the Safety Management Network with ICT Technology

All accidents and incidents that occur within the Group are reported to the Safety Department of the head office in Japan. The Group analyzes the data collected and identifies the underlying issues surrounding accidents and incidents, as well as issues that need to be addressed in order to ensure safety. The results of the data analysis are used as daily safety instructions and reflected in annual safety management policies and medium- and long-term safety management plans. In addition, we have established an ICT-based safety management system for consolidating damage and support systems for natural disasters caused by typhoons, heavy rains, earthquakes, and other natural disasters. We will continue to leverage ICT technology to create an organization that can respond flexibly to health and safety-related risks.